In the rice milling industry, efficiency and quality are two factors that determine long-term success. Every mill owner knows that producing rice with a glossy finish, free from husk residues and scratches, directly affects market value. One of the most crucial machines used in this process is the rice rubber polisher. However, the effectiveness of this machine largely depends on choosing the right Rice Rubber Polisher Supplier who can deliver reliable products and long-term support.

Why a Rice Rubber Polisher is Essential

A rice rubber polisher is designed to enhance the appearance and texture of rice after milling. It removes bran particles, polishes the surface, and improves the rice’s luster, giving it a premium, market-ready look. For commercial rice mills, having an efficient polisher ensures:

Higher Market Value – Well-polished rice attracts better pricing.

Consistency in Quality – Uniform shine and smooth grains build trust with buyers.

Reduced Breakage – Advanced polishers are designed to maintain grain strength.

With demand for high-quality rice on the rise globally, investing in a durable polisher is no longer optional but necessary.

Qualities of a Reliable Rice Rubber Polisher Supplier

When looking for a Rice Rubber Polisher Supplier, you must ensure they meet specific standards of reliability, quality, and after-sales support. Here are some key factors to consider:

1. Product Quality and Technology

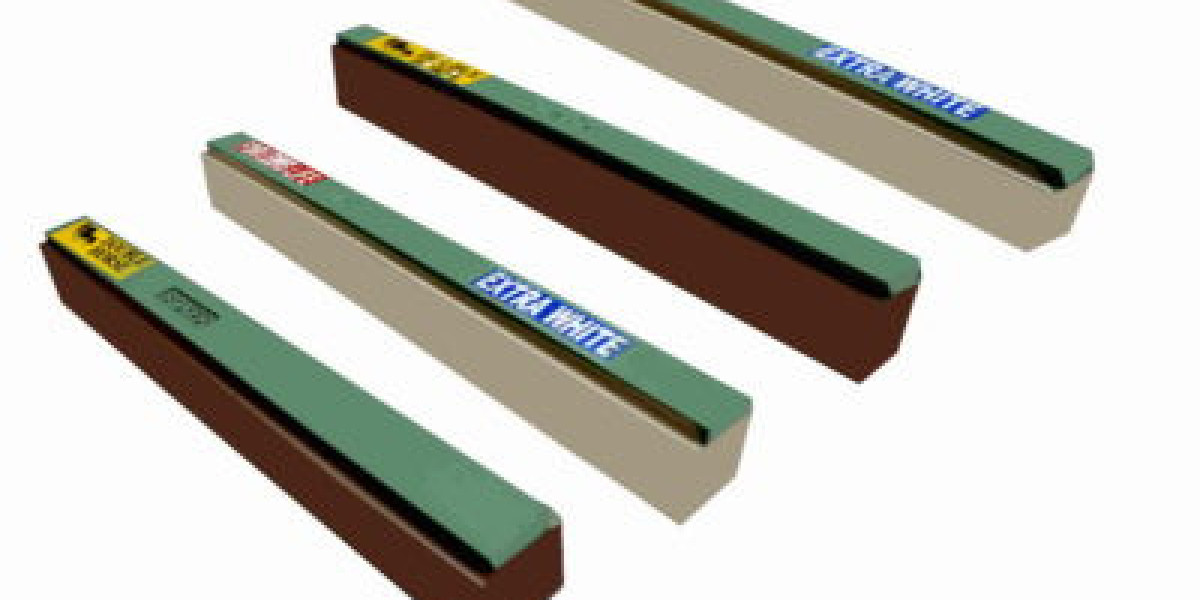

The supplier should offer machines built with modern technology that ensures efficiency, durability, and lower energy consumption. High-quality rubber rollers and components directly affect polishing results.

2. Customization Options

Different rice mills have varying capacities and requirements. A dependable supplier provides customized solutions that match your mill’s production scale.

3. After-Sales Support and Spare Parts

Polishing machines require regular maintenance and replacement of wear parts like rubber rollers. A trustworthy supplier ensures easy availability of spares and timely support.

4. Reputation and Experience

Suppliers with a proven track record in the rice milling industry are more reliable. Checking reviews, testimonials, and industry presence can help you gauge credibility.

5. Cost-Effectiveness

While price matters, choosing the cheapest option may compromise quality. Instead, look for suppliers who balance affordability with performance and long-term durability.

Benefits of Partnering with the Right Supplier

Partnering with the right Rice Rubber Polisher Supplier ensures your rice mill maintains smooth operations without frequent breakdowns. It also gives you access to expert guidance, technical support, and high-quality spare parts that reduce downtime. In addition, a good supplier often keeps pace with the latest innovations, helping your mill stay competitive.

Final Thoughts

Investing in the right rice polishing machine is only half the battle—the other half lies in finding a dependable Rice Rubber Polisher Supplier. By choosing a supplier that offers quality machines, consistent support, and value for money, you can ensure higher productivity, better rice quality, and stronger profitability for your rice mill.

If you are in the process of expanding or upgrading your rice mill, take the time to research and partner with a supplier who aligns with your business goals. A good investment today will guarantee long-term success in the competitive rice industry.