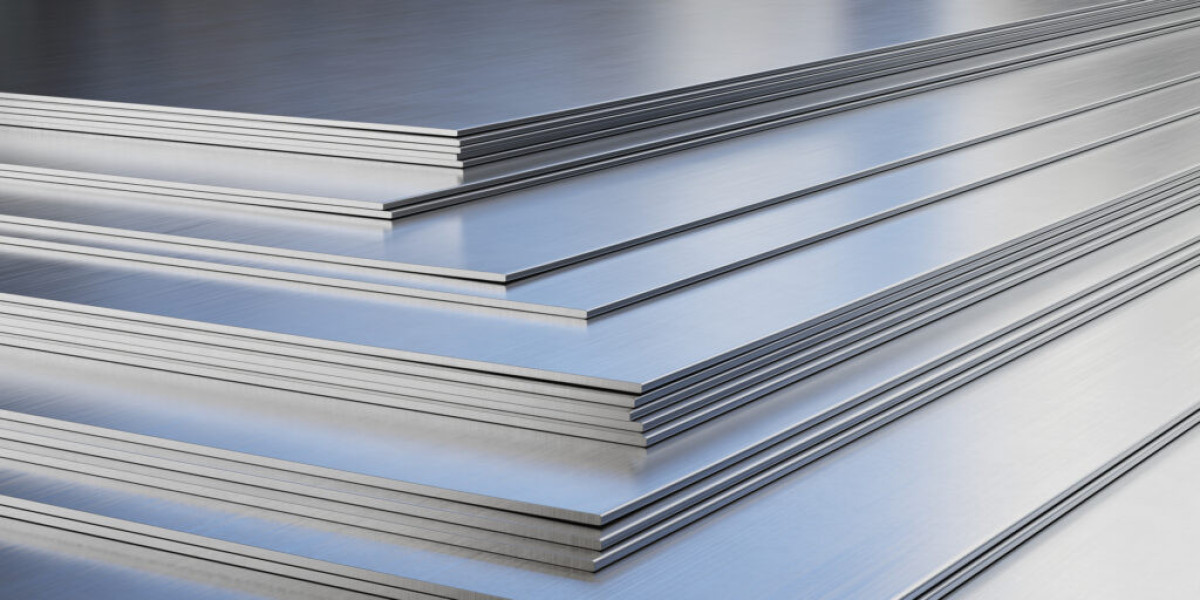

Aluminium is one of the most versatile materials in the world, and aluminium sheet is among its most widely used forms. Known for its lightweight, corrosion resistance, and excellent strength-to-weight ratio, aluminium sheet plays an essential role across industries. From construction and transportation to packaging and electronics, aluminium sheet has become a preferred material that shapes the modern world.

In this blog, we will explore the role of aluminium sheet, its properties, applications, advantages, and how it is transforming industries globally.

Introduction to Aluminium Sheet

An aluminium sheet is a flat, rolled piece of aluminium available in different thicknesses and grades. Depending on the alloy and finish, it can serve purposes ranging from structural support in construction to protective layers in packaging.

Its adaptability makes it valuable in industries that require durability, cost-effectiveness, and sustainability. As aluminium is fully recyclable without losing its quality, aluminium sheets also contribute to eco-friendly manufacturing and green initiatives.

Key Properties of Aluminium Sheet

The properties of aluminium sheet determine its widespread applications. Some of the most important include:

Lightweight – Aluminium has one-third the density of steel, making sheets easier to transport and install.

Corrosion Resistance – Naturally forming an oxide layer, aluminium sheet resists rust and degradation.

High Strength-to-Weight Ratio – Despite being light, aluminium sheets are strong enough for structural applications.

Excellent Thermal and Electrical Conductivity – Ideal for heat exchangers, roofing, and electronic applications.

Workability and Formability – Aluminium sheets can be cut, bent, stamped, and shaped easily.

Non-toxic and Hygienic – Suitable for food packaging and kitchen equipment.

Sustainability – Aluminium is 100% recyclable, reducing the environmental footprint.

Role of Aluminium Sheet in Construction

One of the most significant uses of aluminium sheet is in the construction industry. Modern buildings increasingly rely on aluminium sheets for their combination of strength, aesthetics, and durability.

Roofing and Cladding – Aluminium sheets are corrosion-resistant and provide weather protection.

Curtain Walls and Facades – Lightweight yet strong sheets allow architects to create attractive designs.

Insulation and Panels – Aluminium sheets combined with insulation materials enhance energy efficiency.

Doors and Windows – Their lightweight makes them suitable for framing systems.

By offering durability and low maintenance, aluminium sheets reduce lifecycle costs in construction.

Role of Aluminium Sheet in Transportation

The transport industry benefits enormously from aluminium sheets. With a growing emphasis on fuel efficiency and reducing emissions, manufacturers choose lightweight materials like aluminium.

Automobiles – Aluminium sheets are used in body panels, hoods, roofs, and trunk lids.

Aerospace – Aircraft structures rely on aluminium sheets due to their strength-to-weight ratio.

Marine Industry – Corrosion-resistant aluminium sheets are ideal for boats, ships, and offshore structures.

Railways – Aluminium sheets help reduce overall weight, improving speed and energy efficiency.

By reducing weight while maintaining strength, aluminium sheets improve performance and sustainability in transportation.

Role of Aluminium Sheet in Packaging

Packaging is another sector where aluminium sheets have a critical role. Their hygienic, non-toxic, and non-reactive nature makes them perfect for food and pharmaceutical packaging.

Cans and Containers – Aluminium sheet protects contents from contamination and extends shelf life.

Foil Packaging – Thinner aluminium sheets are used in foils for food, medicines, and cosmetics.

Bottle Caps and Closures – Aluminium sheets provide secure sealing.

Aluminium packaging is lightweight, recyclable, and ensures product safety, making it a sustainable choice.

Aluminium Sheet in Electrical and Electronics

Aluminium sheet is also vital in electrical and electronic applications.

Heat Sinks – Aluminium sheet dissipates heat efficiently, protecting sensitive components.

Consumer Electronics – Lightweight aluminium sheets are used in mobile devices, laptops, and casings.

Electrical Enclosures – Sheets provide durable protection against dust and moisture.

Its thermal and electrical conductivity ensures reliable performance in demanding conditions.

Aluminium Sheet in Household and Decorative Applications

Beyond industries, aluminium sheets are also used in household items and decorative applications.

Kitchen Utensils – Non-toxic aluminium sheets make cookware safe and durable.

Furniture and Interiors – Aluminium sheets add modern, sleek finishes.

Signage and Branding – Their lightweight and smooth finish make aluminium sheets suitable for boards and displays.

These uses highlight the material’s adaptability for both functional and aesthetic purposes.

Benefits of Aluminium Sheet

The growing role of aluminium sheets can be attributed to their multiple benefits:

Versatility – Suitable for structural, decorative, and protective roles.

Durability – Withstands harsh environments and heavy use.

Sustainability – 100% recyclable, supporting eco-friendly practices.

Lightweight – Reduces costs in transportation and construction.

Cost-effective – Long lifespan reduces replacement and maintenance expenses.

Future Role of Aluminium Sheet

The future of aluminium sheet looks promising as industries focus on sustainability, energy efficiency, and innovation. Emerging trends include:

Smart Buildings – Aluminium sheets with integrated solar panels.

Lightweight Transport Solutions – More use in electric vehicles and aerospace.

Advanced Packaging – Sustainable alternatives to plastics using aluminium sheets.

Nanocoatings and Surface Treatments – Enhancing corrosion resistance and appearance.

With continuous research, aluminium sheets will remain at the heart of industrial development.

Conclusion

The role of aluminium sheet in modern industries is vast and growing. From construction and transportation to packaging and electronics, it has become an irreplaceable material. Its unique combination of lightweight, durability, corrosion resistance, and recyclability ensures it will continue to support global industrial needs.