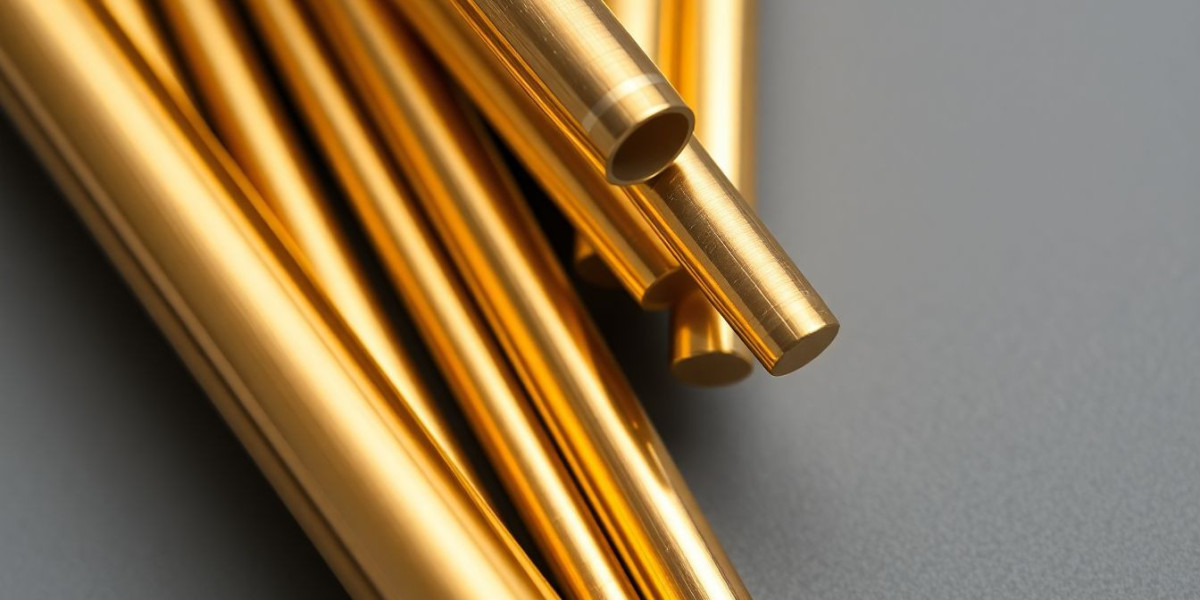

When it comes to choosing the right piping material, factors like durability, resistance to corrosion, and cost-effectiveness play a major role. Brass pipes check all these boxes and more. Made from an alloy of copper and zinc, brass pipes have earned a reputation for reliability in plumbing, construction, marine, and decorative projects. Their golden sheen adds beauty, while their robust performance makes them a dependable choice.

This blog takes you through the features, benefits, and applications of brass pipes, highlighting why they remain a preferred option across industries.

What Are Brass Pipes?

Brass pipes are cylindrical tubes manufactured from a copper-zinc alloy. The exact ratio of copper and zinc varies, resulting in different types of brass suitable for diverse needs. Higher copper content increases corrosion resistance, while higher zinc levels enhance strength.

Brass pipes come in multiple forms:

Seamless brass pipes – No welds, smooth interiors, ideal for high-pressure systems.

Welded brass pipes – Economical and suitable for general applications.

Round, square, and rectangular pipes – Each type designed for specific industrial or decorative purposes.

Properties of Brass Pipes

Brass pipes are valued for their unique physical and mechanical properties:

High Corrosion Resistance – Works well in water supply and marine environments.

Excellent Malleability – Easy to shape, bend, and machine.

Thermal Conductivity – Brass conducts heat efficiently, useful in HVAC and heating systems.

Electrical Conductivity – Supports electrical applications.

Durability and Strength – Performs under pressure and heavy use.

Aesthetic Appeal – Brass pipes shine with a golden finish, perfect for decorative designs.

Antimicrobial Properties – Inhibits bacterial growth, safe for potable water lines.

Benefits of Brass Pipes

Choosing brass pipes offers multiple advantages over other materials:

Long Service Life – They last decades with minimal wear.

Leak Resistance – Provide secure fittings and connections.

Eco-Friendly – Fully recyclable and sustainable.

Resistance to Scaling – Prevents mineral buildup inside pipes.

Low Maintenance – Require little upkeep over time.

Versatility – Suitable for industrial, commercial, and residential uses.

Applications of Brass Pipes

Brass pipes are used in countless applications due to their strength, corrosion resistance, and aesthetic appeal.

Plumbing

Brass pipes are commonly used in hot and cold water supply lines, fittings, and connectors. They resist leaks and corrosion, making them perfect for long-term use.

Marine Systems

In ships, boats, and offshore platforms, brass pipes handle seawater systems thanks to their saltwater resistance.

HVAC Systems

Brass’s thermal properties make it ideal for condensers, radiators, and air conditioning systems.

Industrial Applications

Brass pipes are used in lubricating lines, hydraulic systems, and machinery due to their durability and low friction.

Decorative Works

From railings to furniture design, brass pipes provide both strength and elegance with their golden finish.

Musical Instruments

The acoustic qualities of brass make it essential in manufacturing instruments like trumpets and saxophones.

Automotive Uses

Automobiles use brass pipes in radiator parts, fuel lines, and air conditioning fittings.

Electrical Applications

Brass pipes find use in connectors, grounding systems, and electrical conduits.

Brass Pipes vs. Other Materials

Comparing brass with other pipe materials shows why it remains popular:

Brass vs. Steel: Brass resists rust better, while steel is prone to corrosion.

Brass vs. Copper: Copper is softer; brass is stronger and easier to machine.

Brass vs. PVC: PVC is cheaper but lacks durability and heat resistance.

Manufacturing of Brass Pipes

The process of making brass pipes involves:

Melting Copper and Zinc – Alloys are prepared in a furnace.

Casting – The molten alloy is cast into billets.

Extrusion or Drawing – Billets are shaped into pipes.

Heat Treatment – Pipes are annealed for better ductility.

Finishing and Polishing – Enhances appearance and prevents oxidation.

Testing – Ensures pipes meet strength and quality standards.

Maintenance Tips for Brass Pipes

Brass pipes are low-maintenance, but care extends their lifespan:

Regular Cleaning – Use mild cleaners for decorative brass.

Polishing – Keeps pipes shiny and attractive.

Periodic Inspections – Check for leaks or fitting wear.

Protective Coating – Prevents tarnishing in exposed applications.

Environmental Impact

Brass pipes are eco-friendly because they are 100% recyclable. Recycling brass consumes less energy compared to producing new material, reducing environmental impact and conserving natural resources. This makes brass pipes a sustainable choice for industries focused on green solutions.

Choosing the Right Brass Pipes

When selecting brass pipes for a project, consider:

Application type – Industrial, plumbing, or decorative.

Pipe size and thickness – Based on pressure and fluid requirements.

Alloy composition – More copper for corrosion resistance, more zinc for strength.

Compliance with standards – Ensure pipes meet ASTM, IS, or BS standards.

Future Outlook for Brass Pipes

The global demand for brass pipes is rising due to their versatility and recyclability. With increased focus on sustainable construction and durable materials, brass pipes will continue to be in high demand across plumbing, construction, automotive, and marine industries.

Conclusion

Brass pipes are strong, durable, and versatile, offering unmatched performance in both industrial and decorative applications. Their corrosion resistance, antimicrobial properties, and recyclable nature make them a modern solution for plumbing, marine systems, and construction projects.

From providing reliable water supply lines to adding elegance in architecture, brass pipes remain an indispensable part of everyday life. As industries move toward sustainable and long-lasting materials, brass pipes will continue to hold a prominent place in the future.